Transformer Oil Gas Analyzer

Comprehensive Dissolved Gas and Sulfur Compound Analysis for Transformer Health Monitoring

(Compliant with ASTM D3612, IEC 60567, and extended DBDS sulfur monitoring capabilities)

Overview

Reliable transformer operation depends on early detection of faults within the insulation and oil system. The JAS Transformer Oil Gas Analyzer (TOGA) provides a complete Dissolved Gas Analysis (DGA) solution using Gas Chromatography (GC) to quantify fault gases and sulfur-containing compounds that indicate degradation or contamination.

The analyzer measures the key dissolved gases responsible for identifying arcing, overheating, or insulation breakdown and extends its scope to detect DBDS (Dibenzyl Disulfide) — a critical sulfur compound known to accelerate copper corrosion in transformer oils.

Designed for maximum precision, automation, and reliability, the JAS TOGA system ensures accurate trending, preventive maintenance, and long-term transformer protection.

Method Compliance

- ASTM D3612 A/B/C – Determination of Gases Dissolved in Electrical Insulating Oil by Gas Chromatography

- IEC 60567 / IEC 60599 – Sampling, Analysis, and Interpretation of Dissolved Gases in Transformer Oils

- DBDS Analysis – According to IEC 62697-1 for detection and quantification of dibenzyl disulfide (DBDS)

These established methods cover both traditional fault gas analysis and sulfur degradation monitoring, providing complete insight into transformer condition.

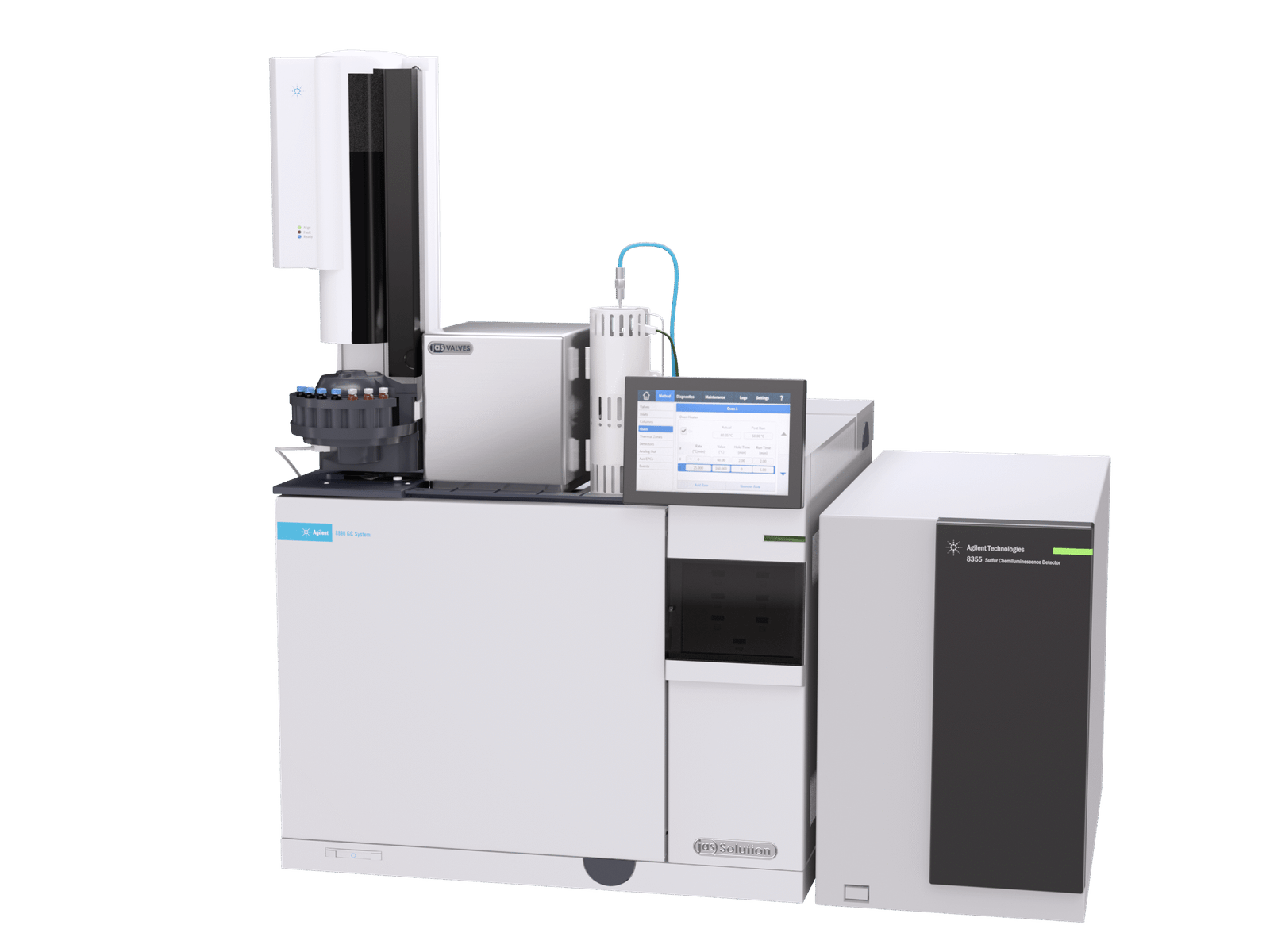

System Configuration

The JAS Transformer Oil Gas Analyzer integrates a multi-detector GC platform with advanced automation and sample handling flexibility:

- Dual Detector Configuration: TCD + FID for permanent gases and hydrocarbons

- Optional AED (Atomic Emission Detector): Enables multi-element detection (C, S, N) for extended analysis — allowing DBDS, H₂S, and sulfur traces to be monitored simultaneously with fault gases

- Sample Handling: Vacuum extraction or headspace sampling per ASTM D3612

- Column Configuration: Optimized column set for complete separation of H₂, CO, CO₂, CH₄, C₂H₂, C₂H₄, C₂H₆, N₂, O₂, and DBDS-related compounds

- Valve System: Automated 6- or 10-port switching with optional 4-port venting for high methane samples

- Temperature-Controlled Zones: Ensures analytical stability and repeatability

- Integration: Compatible with Agilent OpenLab CDS and JAS TOGA Reporting Suite

Performance Highlights

- Determination of nine key diagnostic gases plus DBDS and other sulfur species

- High sensitivity and accuracy with sub-ppm detection limits

- Optional AED III detector for multi-element sulfur/nitrogen/carbon correlation

- Fast analysis cycle (<15 minutes) with automated valve switching

- ASTM/IEC-compliant validation with built-in calibration checks

- User-configurable sampling (manual or automatic headspace)

- Long column and detector lifetime with protective backflush system

Software and Reporting

Powered by JAS Report Generator and Hydrocarbon Expert / OpenLab CDS, the software delivers comprehensive data management and diagnostic tools:

- Automatic calculation of Total Dissolved Combustible Gases (TDCG)

- Fault interpretation based on Duval Triangle and Rogers Ratio

- Trending of gas evolution and degradation rate

- DBDS concentration reporting and correlation with oil aging

- Multi-element result integration when AED is configured

- Export to Excel, CSV, or LIMS formats for easy plant integration

Options and Accessories

To meet specialized testing requirements, JAS offers modular configurations:

- AED III (Atomic Emission Detector): Multi-element C/S/N analysis for DBDS and trace sulfur compounds

- 4-Port Venting Module: For high methane concentration venting and pressure control

- Headspace Sampler or Vacuum Extraction Unit

- Multi-stream ValveBox: For automatic multi-transformer sample sequencing

- Calibration Gas System: Automated calibration for ASTM D3612 and DBDS standards

- Extended Sulfur Analysis Package: Combines TOGA + DBDS + H₂S trace detection in one platform

Why Choose JAS Transformer Oil Gas Analyzer

- Complete DGA + DBDS solution in a single analyzer

- ASTM, IEC, and IEC 62697-1 compliant

- Proven reliability in power utilities and transformer OEM labs

- Optional AED III integration for enhanced sulfur trace performance

- Custom-built GC systems using Agilent hardware and JAS valve technology

- Supported by JAS global service and calibration network

Applications

- Transformer health diagnostics and preventive maintenance

- DBDS monitoring for copper corrosion risk detection

- Power plant and utility laboratory analysis

- Quality control of transformer insulating oil

- Research and reliability testing of insulating materials

JAS Transformer Oil Gas Analyzer —

Advanced DGA and DBDS sulfur detection for predictive transformer maintenance and long-term reliability.