SimDis Analyzer

Overview

Simulated Distillation (SimDis), based on Gas Chromatography (GC), is one of the most widely used analytical techniques in the petrochemical industry. A SimDis report provides valuable insight into the boiling point distribution of crude oils and petroleum fractions.

This information is crucial for refinery engineers to optimize distillation operations, improve process control, and ensure cost-effective production.

A robust and reliable SimDis Analyzer is therefore an essential tool for efficient refinery performance.

Method Compatibility

JAS SimDis Analyzers are fully configurable to meet various international standard methods for oil samples with differing final boiling points. Depending on method requirements, different columns, analytical parameters, and reference standards may be used.

Supported Methods Include:

ASTM D7096, D2887, D5307, D7398, D7213, D7169, D6352, D7500, D7900, IP 480, IP 507, IP 545, IP 601, EN 15199-1/2/3, ISO 3924, and DIN 51435.

System Configuration

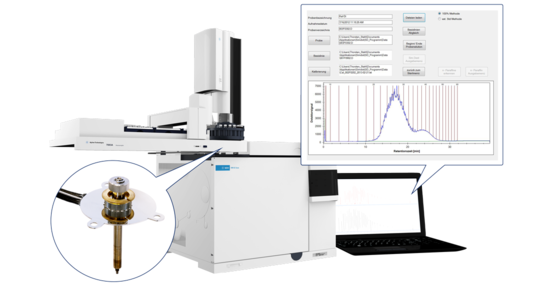

UNIS 3100 HT Series

Each JAS SimDis Analyzer can be equipped with:

- UNIS 3100 HT PTV Inlet, or

- UNIS HT SimDis (CoC) with patented SimDis liner,

depending on the method’s specific requirements.

Both injectors are temperature-programmable up to 500 °C, ensuring flexibility for a wide range of samples and conditions.

Software Integration

Every JAS SimDis Analyzer is fully tested and delivered with the JAS SimDis Software Plugin, integrated with SIMDIS Expert— the most powerful and user-friendly simulated distillation data analysis software available today.

Key Software Features

- Customizable user access levels for enhanced security

- User-defined cut points

- ASTM D86 and D1160 correlations

- Calculations for key physical properties: liquid/vapor ratio, RVP, NOACK volatility, Cetane index, flash point, and more

- On-screen analysis: chromatograms, plots, and calculations displayed together

- Customizable reports and templates

- Side-by-side comparison of multiple reports

- Advanced peak integrator and intelligent elution detection algorithm

- Automatic recalculations when elution marks are adjusted

- Boiling point table customization

- Crude oil blending simulations

- Built-in Merge Expert for DHA data integration (e.g., ASTM D7900 with D7169/D6352)

- Support for multi-detector channels (FID, SCD, MS)

- Optional MS module for aromatics and saturates group-type analysis

- Automatic export in Excel, ASCII, or CSV format (e.g., to LIMS)

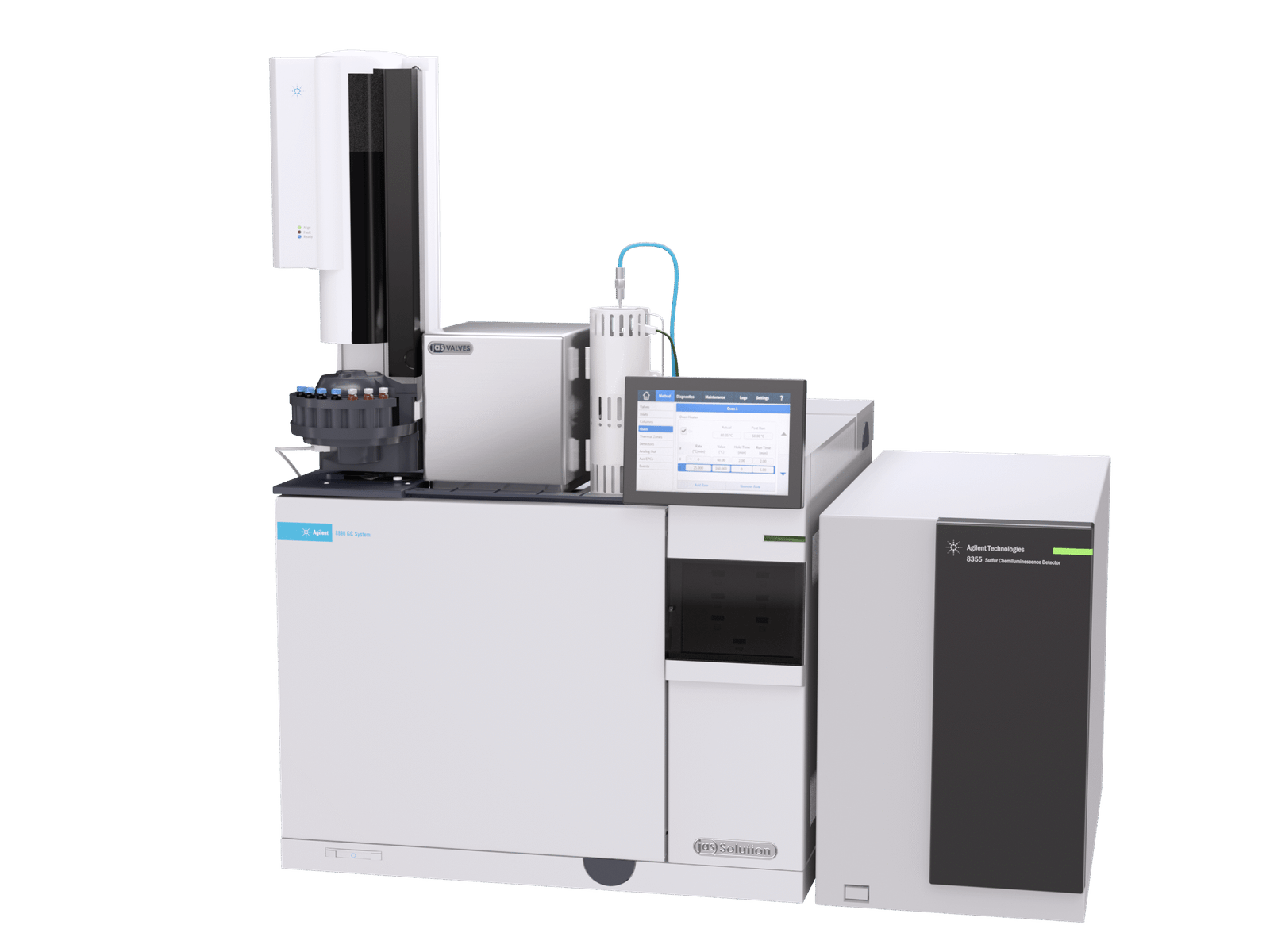

Optional Upgrade

AED III – Atomic Emission Detector

JAS offers a unique upgrade option — the AED III, a newly redesigned Atomic Emission Detector with improved performance and extended capabilities.

This detector enables multi-element SimDis analysis in a single run, providing simultaneous data for Carbon, Sulfur, and Nitrogen — all in one comprehensive report.

Why Choose JAS SimDis

- Fully compliant with multiple global ASTM, EN, and ISO methods

- Proven accuracy, robustness, and reliability

- Integrated hardware–software solution for complete analysis workflow

- Backed by JAS expertise in analytical system design and process optimization